Craved Glass

Most people have a basic picture in their minds when they hear the term “Carved glass” basically visualizing that the glass surface has been turned white! It’s no longer “clear”. However, that’s NOT true.

At Shenzhen Dragon Glass, we are proud to provide two methods to produce carved glass, and we combine a number of different techniques to achieve different effects. We give extra depth to many designs, creating a combination of polished and etched areas.

Production Process Technology

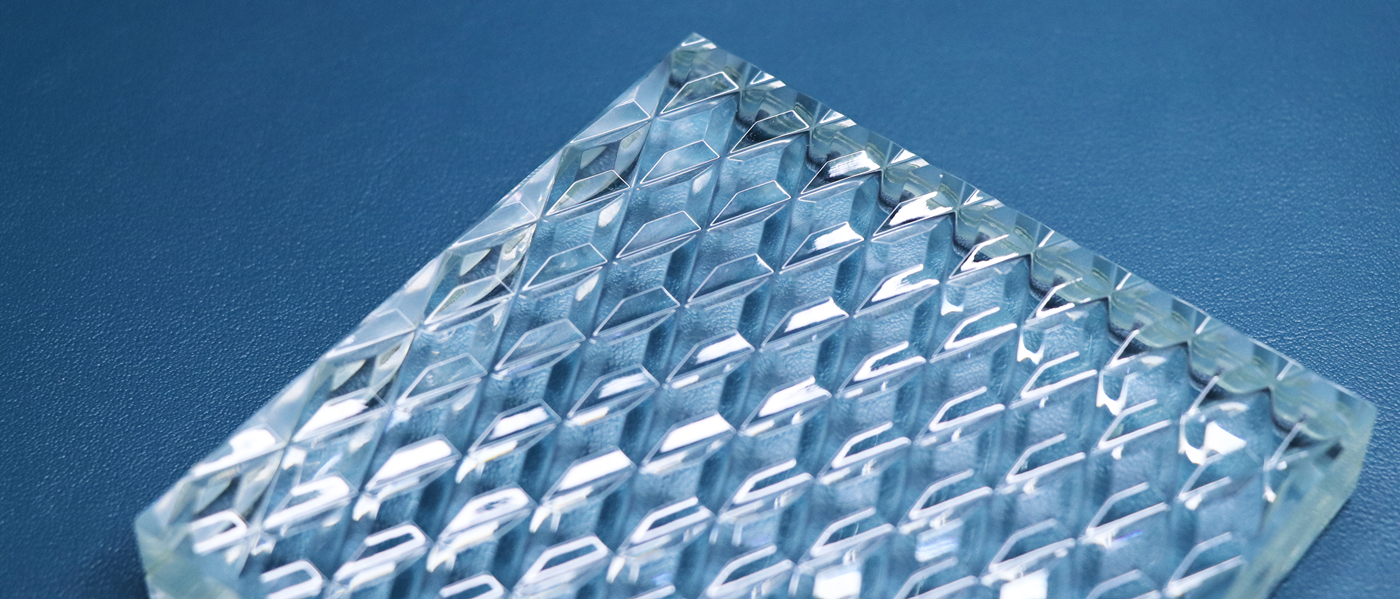

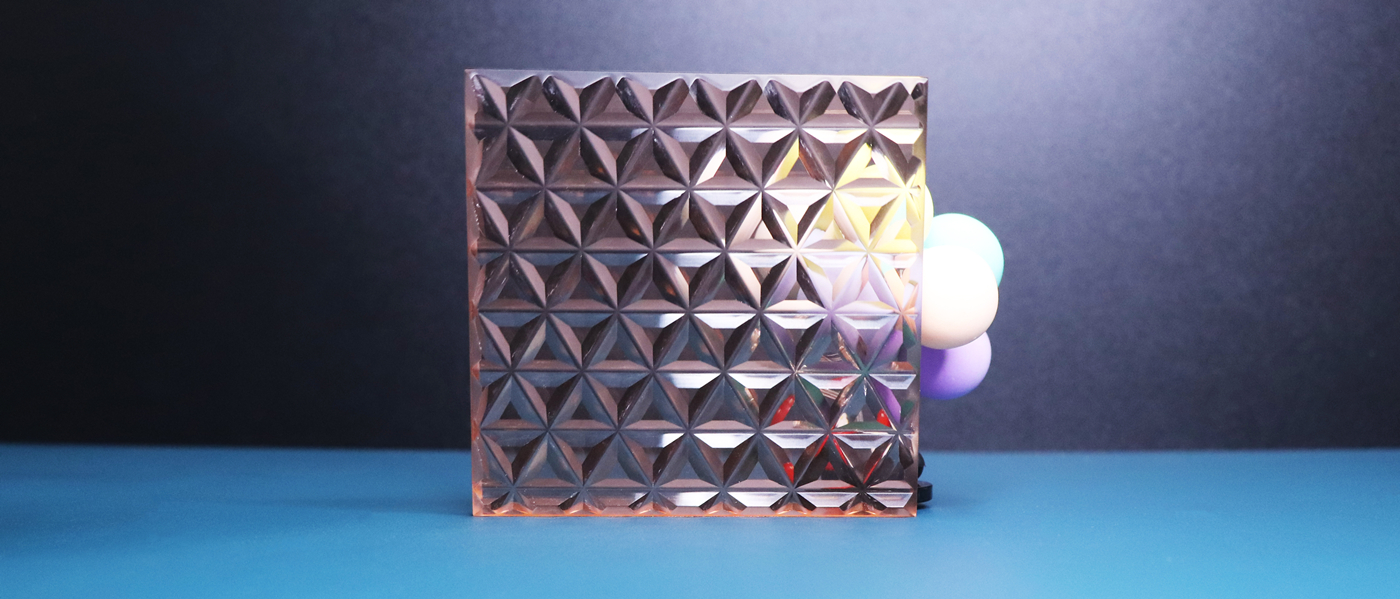

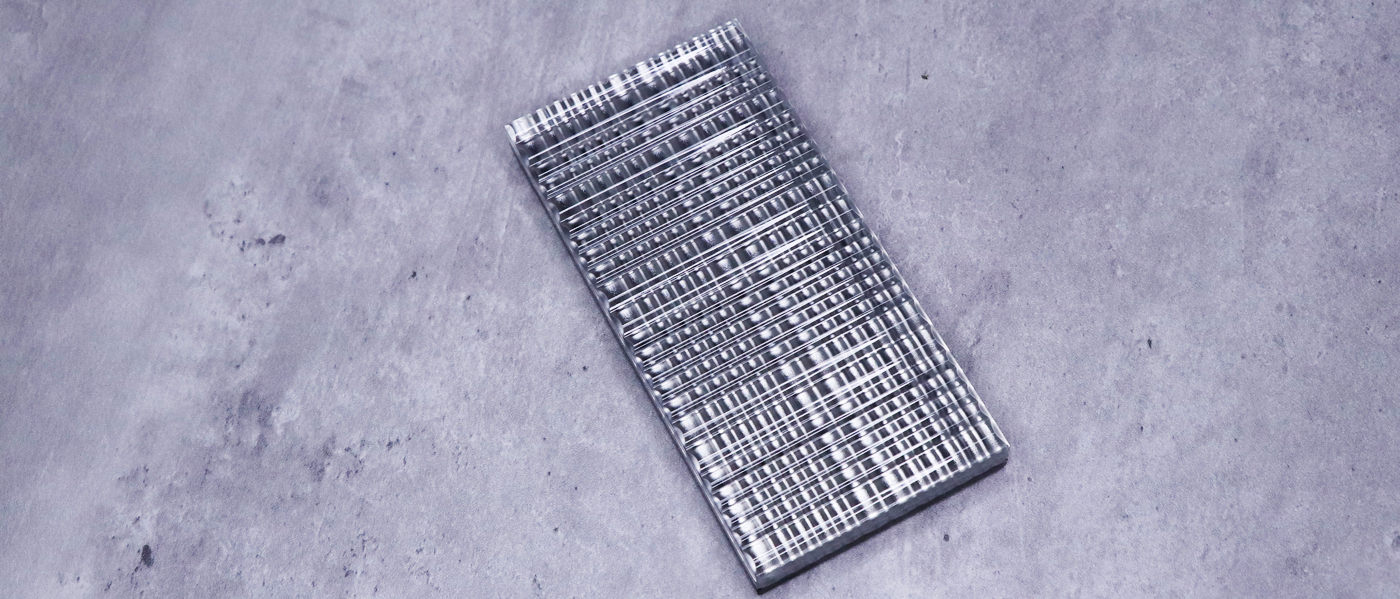

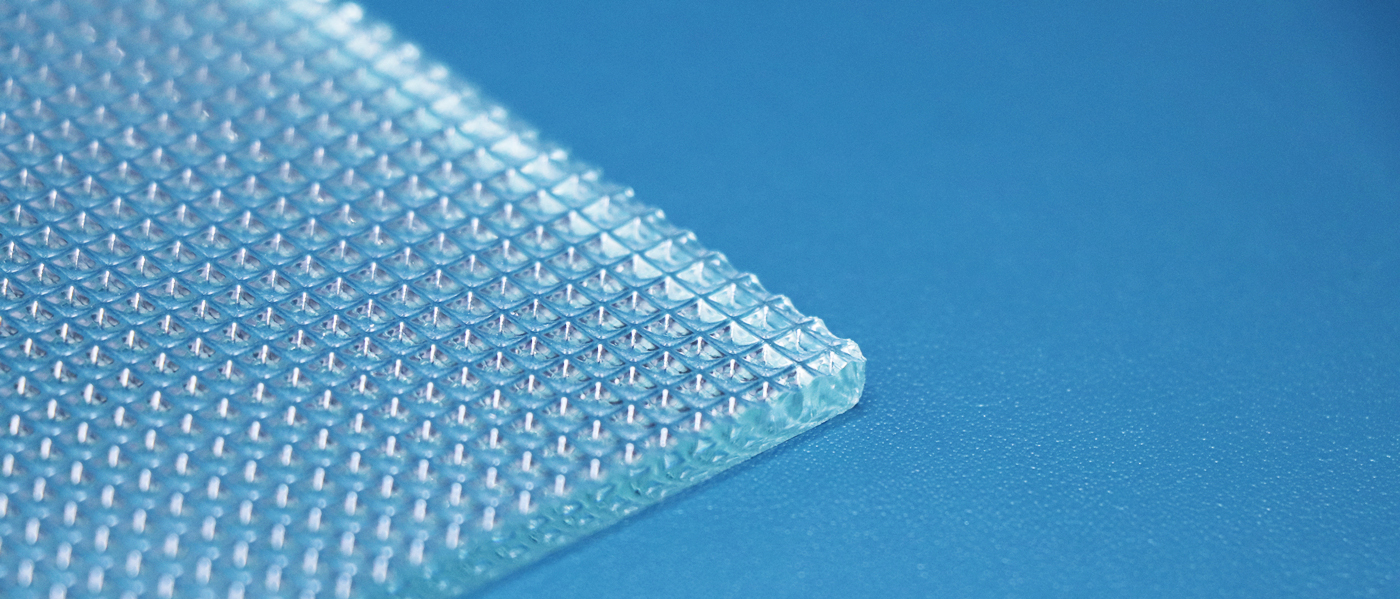

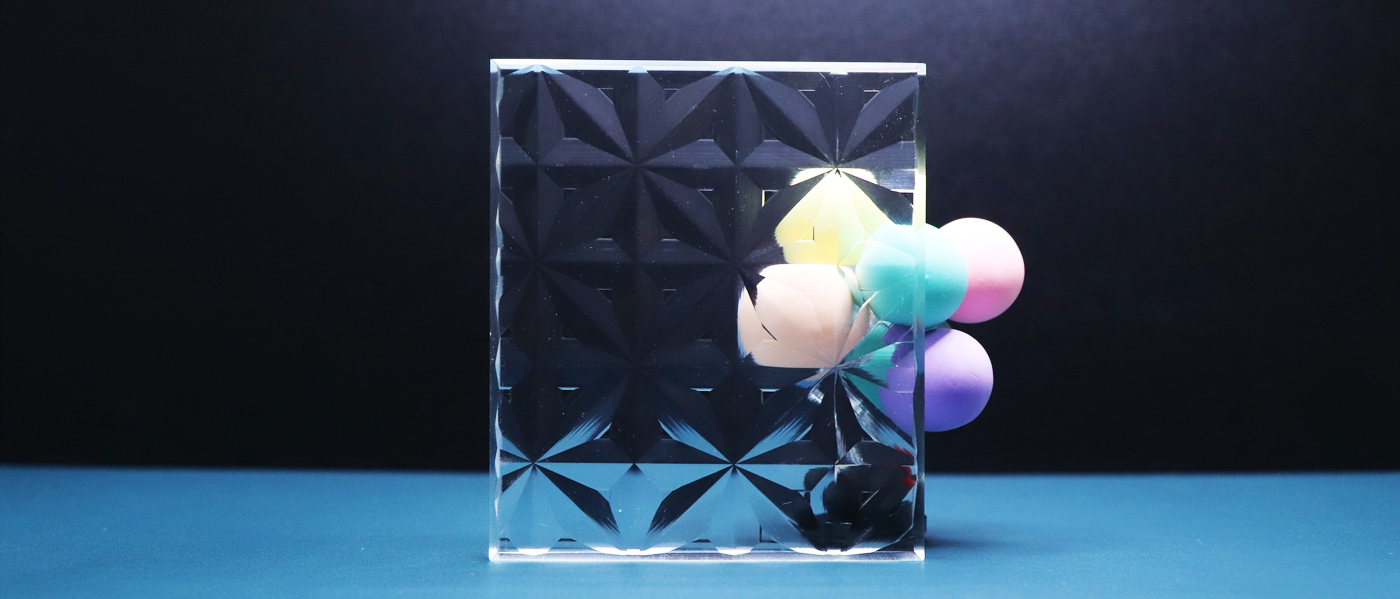

Carved glass can be fabricated by modern computer-controlled carving machines. Firstly design the patterns as your need in CAD drawing and input them into the computer, later transform the patterns into CNC engraving glass machines. The engraving machines will carve the glass and polish the lines to form the exactly designed patterns. This unique fabrication method produces a distinctive 3D appearance on the glass while maintaining its clarity.

Carved glass can also be fabricated by hand with sandblasting/etching technique whose decorative design has been cut into the surface by the corrosive action of an acid. An etched-glass surface may be either rough and frosted or satiny smooth and translucent, depending largely on the composition of the glass and the amount of time the glass is exposed to the acid.

Features & Benefits

- Multiple pattern designs, OEM is available. Custom your own pattern.

- Multiple pattern depths to the segment of the design create a drastic 3D visual look.

- Provides privacy while demonstrating an incredibly beautiful Architectural Glass finish. Watch as beauty and elegance come together.

- Sturdy and scratch-resistant surface.

Product Specifications

- Glass Thickness: Any combination of flat glass 8mm to 19mm

- Max size: 2440*3660mm

- Glass color: clear, ultra-clear, grey, bronze, blue, green, etc

- Shape: flat/curved

- Capacity: 1500 SQM/DAY

- Quality: subject to CE/ASTM/AS/ISO9001/BS/CE

- Production time: 15~25 days

- Further process: laminated, insulated, etc to enhance other performance